In today’s volatile logistics landscape, supply chain disruption isn’t the exception—it’s the norm. Between trade wars, labor shortages, shifting customer expectations, and international uncertainty, logistics leaders are under constant pressure to deliver more with less.

That’s why a well-designed supply chain strategy has never been more important.

Too often, logistics leaders are consumed by day-to-day execution: managing shipments, resolving delays, and firefighting inventory challenges. But without a clear supply chain strategy, even the most efficient operations risk falling short of customer expectations or becoming vulnerable to disruption. According to the Logistics Bureau, a 5% reduction in supply chain costs can double a company’s net profit—proving that logistics isn’t just an operational function, it’s a financial lever.

While many teams focus on day-to-day execution, the organizations seeing long-term success in 2025 are those that invest in building custom, integrated supply chain strategies—strategies that align logistics operations with broader business goals.

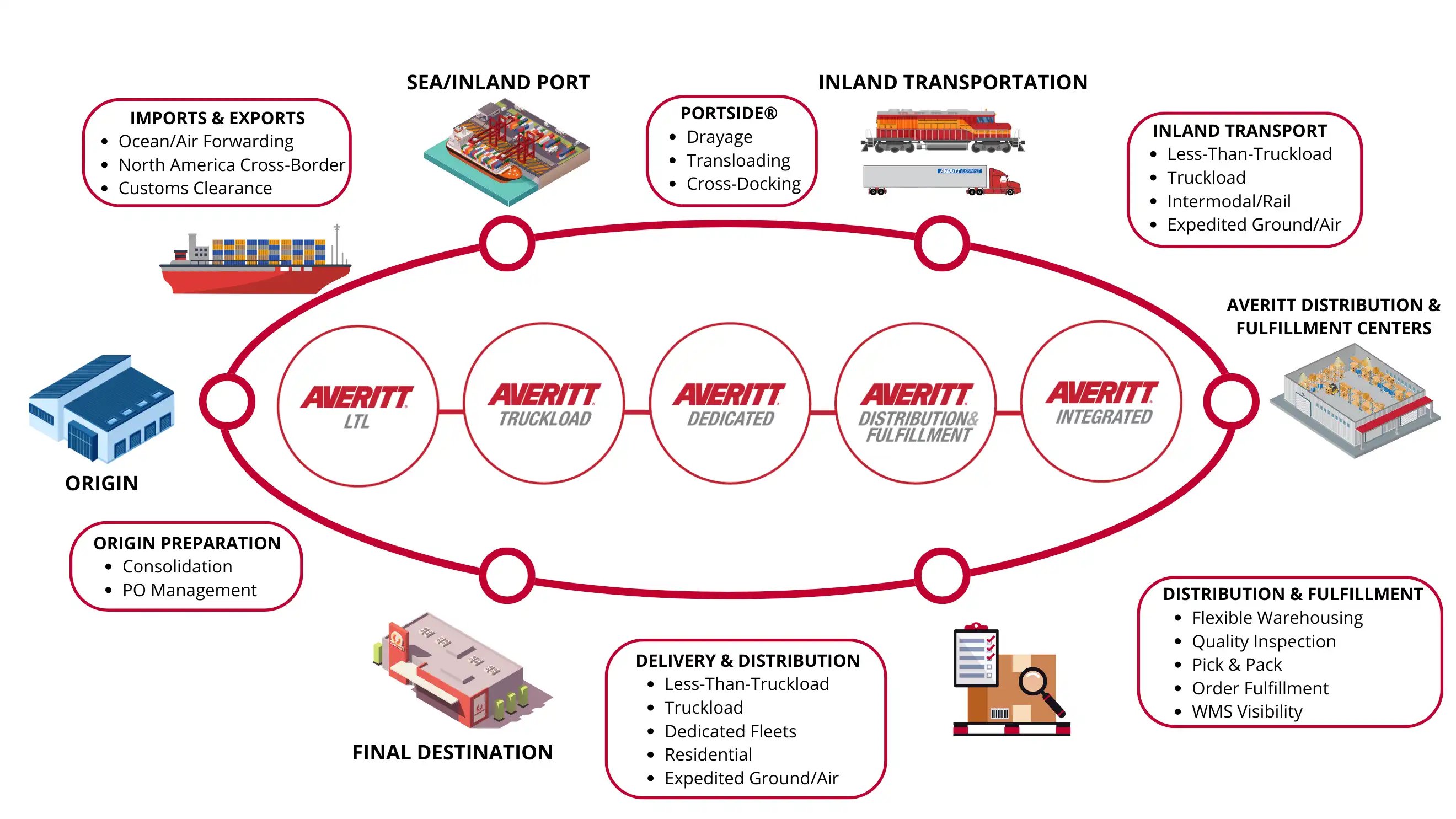

In this guide, we’ll explore what a supply chain strategy is, break down common models, and show how a tailored approach can unlock efficiency, reduce costs, and enhance flexibility. We’ll also highlight real-world case studies from businesses that have transformed their logistics through Averitt's Power of One: one partner delivering endless possibilities.

What Is a Supply Chain Strategy?

A supply chain strategy is the framework that guides how your company moves goods from origin to destination. It’s more than just selecting carriers or managing warehouse space—it’s about designing a logistics network that meets your customer service levels, manages cost, and scales with your business.

Unlike day-to-day operations, supply chain strategy answers critical big-picture questions:

- Where should inventory be stored to reduce delivery times?

- What’s the ideal balance between cost and service level?

- Should we rely on in-house assets or third-party logistics?

- What’s our risk tolerance for disruption?

The best supply chain strategies aren’t static. They evolve with market conditions, customer expectations, and your business growth trajectory.

Why Supply Chain Strategy Matters in 2025

The past few years have made one thing clear: reactive logistics is no longer sustainable. From pandemic disruptions to port congestion and shifting trade policies, supply chains have become a focal point of risk—and opportunity.

That’s why strategic planning is no longer a luxury; it’s a competitive necessity.

According to the OECD Supply Chain Resilience Review, aggressive reshoring efforts—often seen as a quick fix for supply chain disruptions—could reduce global trade by up to 18% and lower GDP by as much as 12% in affected countries. The takeaway? Overcorrecting by bringing everything close to home can backfire.

Instead, experts recommend a more nuanced strategy—one that emphasizes geographical diversification, builds in redundancy, and leverages smart partnerships to create flexible, shock-resistant networks. The right supply chain strategy doesn’t just respond to disruption—it’s designed to anticipate and withstand it.

The Cost of Not Having a Supply Chain Strategy

What happens when a business operates without a documented logistics strategy? In short: misalignment, rising costs, and missed opportunities. Without a clear framework, companies often:

- Rely on outdated carrier networks that no longer meet delivery expectations

- Overpay for expedited freight due to poor inventory positioning

- Struggle with disconnected systems that create blind spots

- Lack contingency plans for weather events, labor strikes, or global disruptions

These aren’t rare occurrences. In Averitt’s experience, many companies initially come to us after struggling with multiple disconnected providers, poor tracking visibility, or excessive accessorial fees. That’s why our approach starts with strategy—then follows with execution. Our PO1 model connects transportation, warehousing, and final mile through one partner and one cohesive plan.

Common Types of Supply Chain Strategies (with Examples and Industry Insights)

Selecting the appropriate supply chain strategy is crucial for aligning operations with business objectives. Below are common strategies, each illustrated with hypothetical examples and supported by industry statistics:

1. Lean Supply Chain

Definition: Emphasizes efficiency by minimizing waste and reducing inventory levels. Ideal for businesses with stable, predictable demand.

Example: A regional manufacturer of commercial lighting fixtures ships to distributors on a predictable schedule. By maintaining low inventory and working with a reliable transportation partner for just-in-time delivery, they minimize carrying costs and avoid overproduction.

Industry Insight: According to KPMG International, businesses should focus on cost-to-serve analyses to enhance efficiency, a core principle of lean supply chains.

2. Agile Supply Chain

Definition: Prioritizes flexibility and responsiveness to rapidly changing market demands. Suitable for industries with high variability and customization.

Example: A health and wellness brand that frequently introduces new product SKUs and runs flash promotions needs an agile supply chain. Their distribution and fulfillment centers must pivot quickly, and transportation providers need to accommodate rapid volume fluctuations.

Industry Insight: According to a 2025 report from the Hackett Group, approximately 50% of supply chain leaders are testing Generative AI technologies to build more resilient and agile supply chains.

3. Hybrid Supply Chain

Definition: Combines elements of both lean and agile strategies to balance efficiency with flexibility.

Example: A consumer electronics company uses a lean model for best-selling items but keeps buffer inventory and flexible shipping options for new launches. With warehousing solutions near key markets, they avoid overstock while meeting tight delivery windows.

Industry Insight: In 2023, 37% of companies reported changing their operating model, indicating a shift towards hybrid supply chain strategies. (SMB Guide supply chain report)

4. Asset-Based vs. Non-Asset Logistics Models

Definition:

- Asset-based providers own transportation and distribution infrastructure.

- Non-asset providers act as brokers, offering flexibility through networks of partners.

Example: A national appliance retailer chooses an asset-based partner like Averitt for dependable final mile delivery. In contrast, a small e-commerce startup may opt for a non-asset 3PL to avoid fixed costs.

Industry Insight: The logistics sector is experiencing growth in both models, with smaller private firms quadrupling earnings over recent years. (Holland & Knight logistics report)

5. Centralized vs. Distributed Fulfillment

Definition:

- Centralized fulfillment reduces overhead by consolidating inventory.

- Distributed fulfillment places inventory closer to customers to reduce delivery time.

Example: A B2B medical supplier centralizes warehousing for simplicity, while an online home décor brand uses regional distribution centers to meet 2-day delivery standards.

How to Build a Custom Supply Chain Strategy

Designing a supply chain strategy isn’t about checking boxes—it’s about aligning logistics with what actually drives your business forward. At Averitt, we help shippers build strategies around four key pillars:

1. Customer Expectations Come First

Start with what your customers need—then work backward. Whether it's same-day delivery, special handling, or cost predictability, your supply chain should be shaped around service-level expectations.

💡 Case in Point: All South Flooring

To better serve dealers with tight delivery windows, All South Flooring partnered with Averitt to implement drop-and-hook trailers and integrated booking tools—reducing delays and increasing satisfaction.

Want to hear how strategy turns into real-world results? In this video, All South Flooring leadership shares how partnering with Averitt helped them streamline delivery, increase flexibility, and support scalable growth—without investing in their own fleet.

My name is Greg Capell. I'm the VP of Operations and Finance here at All South Flooring. We're a wholesale floor covering distributor. We consider ourselves to be providers of solution-driven products, and really try to build our business on relationships, industry, knowledge, expertise, and providing quality products, competitive pricing, and the highest service levels that we can do. We can have the best product out there, but if we can't deliver it or meet a home closing or a project deadline, it doesn't really add any value. And that's where we lean on Averitt so much to deliver that. It's been an outstanding relationship and has only gotten better After the years have gone by, We kind of approached Averitt with the proposition of, "Hey, can you guys drop an empty trailer to us at our warehouse?" Each day they went back to their team and found a way to make it happen. And what it's done is increase our service levels exponentially to our customers because we're able to load up to, and even after close of business in some instances. And when we go talk to our customers, it's almost like we're carrying Averitt with us in our product bag, right? We can deliver a product to you in one to two days for pretty much our entire footprint of our territory. So it gives us flexibility, it gives us a competitive advantage. Our customers understand their business is important to us, but they are also important to us as a person. That's our culture. We see each other as a family, so therefore that reflects with our customers. We are there when they need us. As a young business that you grow through multiple phases, and a piece of that is trying to find different technologies that increase your efficiency and allow you to operate at higher level. When Maritza approached us for Averitt Connect, once we were finally able to sit down and see a demo and see the practical application of the software, it was a no brainer for us. It made just the ease of quoting shipments, generating bill of ladings. The paper and workflow that we have internally, Averitt Connects. It's a huge value add for us. Als, it's a fast growing company and our goal is to continue to grow with them. As they grow, we grow. We like to ship everything LTL, and as that volume picked up with Averitt, they garnered more of that business. And we still use Averitt for our truckload shipments. So we have domestic suppliers that we leverage their inventory and pull out of their inventory, and we try to do that as a truckload basis to keep the cost down. And Averitt is always quick to turn around a quote for us and is always very competitive. We found our home here in the southeast, and then really what we want to do is become the premier flooring distributor, resilient flooring distributor in the Southeast. I think it suits Averitt's footprint well in that they service our entire territory and where we operate. And as much as we can, we love to continue to feed that business and develop that relationship with them. We provide for them more than one service. LTL, Truckload, Distribution and Fulfillment, local moves and Averitt Connect. All South Flooring is a prime example of the Power of One.

2. Geographic Positioning is Strategy, Not Logistics

Where you position your freight matters just as much as how you move it. Centralized warehousing may cut costs, but distributed fulfillment can get you closer to the customer—and cut days off delivery timelines.

💡 Case in Point: Spectra Gutter Systems

With growing import volume and limited distribution bandwidth, Spectra worked with Averitt to build a near-port distribution model and improve final-mile integrity. The result: lower transit times and happier customers.

In this video, Alan Hensley from Spectra Gutter Systems break down how Averitt helped them overcome port congestion, improve inventory flow, and eliminate costly delays. It’s a clear example of how strategy and execution go hand in hand.

My name is Alan Hensley. I work for Spectra Gutter Systems and based in Atlanta, Georgia. We're the largest manufacturer of what they call gutter rainware. We manufacture from the raw material that comes in, and then we have our branches around the country, and we retail it out from there. Our manufacturing has grown, and we are now into importing. And so that's allowing us to use Averitt for importing. They also have the fulfillment centers where we can store stuff or have it transloaded. Alan contacted me and wanted to know if we could be of assistance. We were able to create a solution where Averitt will dray the containers when they come in to either our distribution and fulfillment centers to transload or directly to Spectrum gutters. Back in 2017, we started out using Averitt to do some of our truckload logistics to our different branches. And over time, we integrated the LTL system as well into a 3PL system we already have. They're able to help us get our new product we're having made overseas into the port and then to get it to our facility in Atlanta. I don't have to worry about having different people to pick it up at the port and different people to get it to us. It's just one place, one stop, and they handle it from there. Our technology will give them complete visibility of their product from the time that it ships to the time it arrives to their door. You know, we want it looking pristine when it gets there. The box is not crumpled and torn up. That says a lot as well. So they transport that when it leaves our facility in that condition and it gets to the customer in that condition. Our goals for the future for Spector Gutter Systems is to be in all the states, across the country. We have a five-year goal to have be a billion dollar a year company, and we're gonna need lots of transportation. They're gonna need a great partnership like we have, with Averitt. This allows us not to have to slow down, but we can keep it going to where we have facilities to store it in in the fulfillment centers that are out near our branches. And then we can propagate it out from there and it goes across the country. So they'll be a big part of helping us to grow. I think we can help them put their product in different locations to beta test on areas they wanna grow in without making a full commitment of staff and resources. That is a great enhancement and a great partnership because as we grow, we don't have to necessarily put on drivers and trucks right away to be able to do that. We can use their system and their dedicated drivers to be able to do that. There's that Power of One to help us to grow. Well, the reason why we're calling it Power of One, is Spectra Gutter Systems are using our truckload, our LTL, and are integrated to provide solutions for them. We are also expanding into distribution and fulfillment as well as possibilities of dedicated that would help them grow closer to that one billion dollar goal. It's the power of one company being able to meet all of my logistic needs. The deal about Power of One - I always like to come back to the relationship. Averitt believes in taking care of the relationship and and the person, not just the business. Whatever my problem is, they are solution to help us to solve it. And they will go to whatever extreme it needs to be to make it. Whether it's making room in a warehouse, it doesn't matter. I want a partner that's like that and Averitt fulfills that for us.

3. Simplicity Beats Fragmentation

Working with dozens of disconnected providers adds layers of friction. A unified logistics partner can reduce complexity and enable better data flow, visibility, and coordination.

💡 Case in Point: Automotive Manufacturer

A global automotive manufacturer was managing over 30 Mexican vendors—until Averitt implemented a single cross-dock and consolidated pickups at the border, streamlining delivery to meet OEM timelines.

4. Scalability Must Be Built In

Can your supply chain flex when demand spikes—or dips? A resilient network should scale without contract renegotiations, system reboots, or service disruption.

Ask your team:

- Are we using the right transportation modes for each lane?

- Do we have built-in redundancy (e.g., alternate ports, warehousing options)?

- Can we scale without renegotiating contracts or overpaying?

- Are we spending too much time managing vendors instead of performance?

- Do we have real-time visibility across inbound, warehousing, and final mile?

Final Thought: Strategy Is the Supply Chain Advantage

In today’s environment, the difference between a good supply chain and a great one isn’t just cost or speed—it’s clarity of purpose. The most successful shippers aren’t reacting to market shifts—they’re planning for them. They know where they’re going and have a partner who can help them get there.

At Averitt, we don’t just provide services—we help you design and execute supply chain strategies that adapt, scale, and deliver real value. With one trusted team handling your transportation, warehousing, fulfillment, and final mile delivery, you can move forward with confidence and simplicity.

Whether you're reevaluating your network, struggling with inefficiencies, or planning for growth, let’s build your supply chain strategy—together.

👉 Ready to get started? Fill out the form below to connect with one of our transportation specialists.

.png?width=542&height=179&name=PNG-Averitt%2055%20Years%20RED%20ODFIP%20(1).png)

.webp)