Inbound logistics is often the unsung hero of the supply chain. It sets the stage for everything that follows, yet it’s where many supply chains begin to fray. With market volatility, rising import costs, and supply chain disruptions continuing into 2025, it's time to ask: Is your inbound model helping or hurting you?

To help us rethink what inbound logistics should look like today, I sat down with Ed Smith, Averitt’s Vice President of Distribution and Fulfillment. Ed has spent over two decades at Averitt’s evolving our PortSide® Services and Distribution and Fulfillment network into a seamless, integrated solution. His advice?

Stop letting too many hands touch your freight.

Watch my interview with Ed below.

Too Many Hands, Too Many Headaches

"Gaps mean fear," Ed said during our conversation. "If you start piece mailing those things (links in the supply chain) together, then that's where it weakens the the armor. Because right then, you start to have gaps, whether it's communication gaps, visibility gaps."

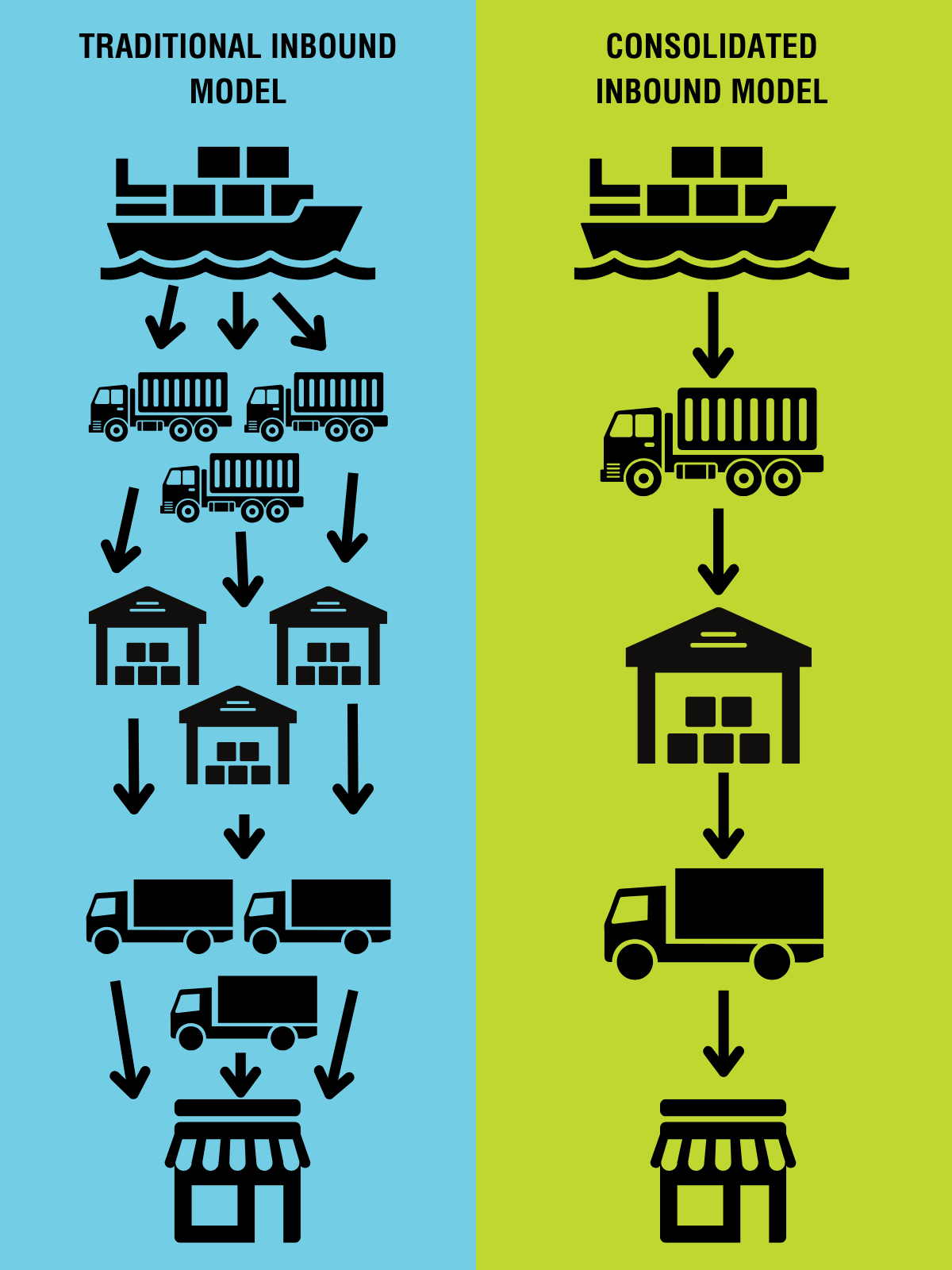

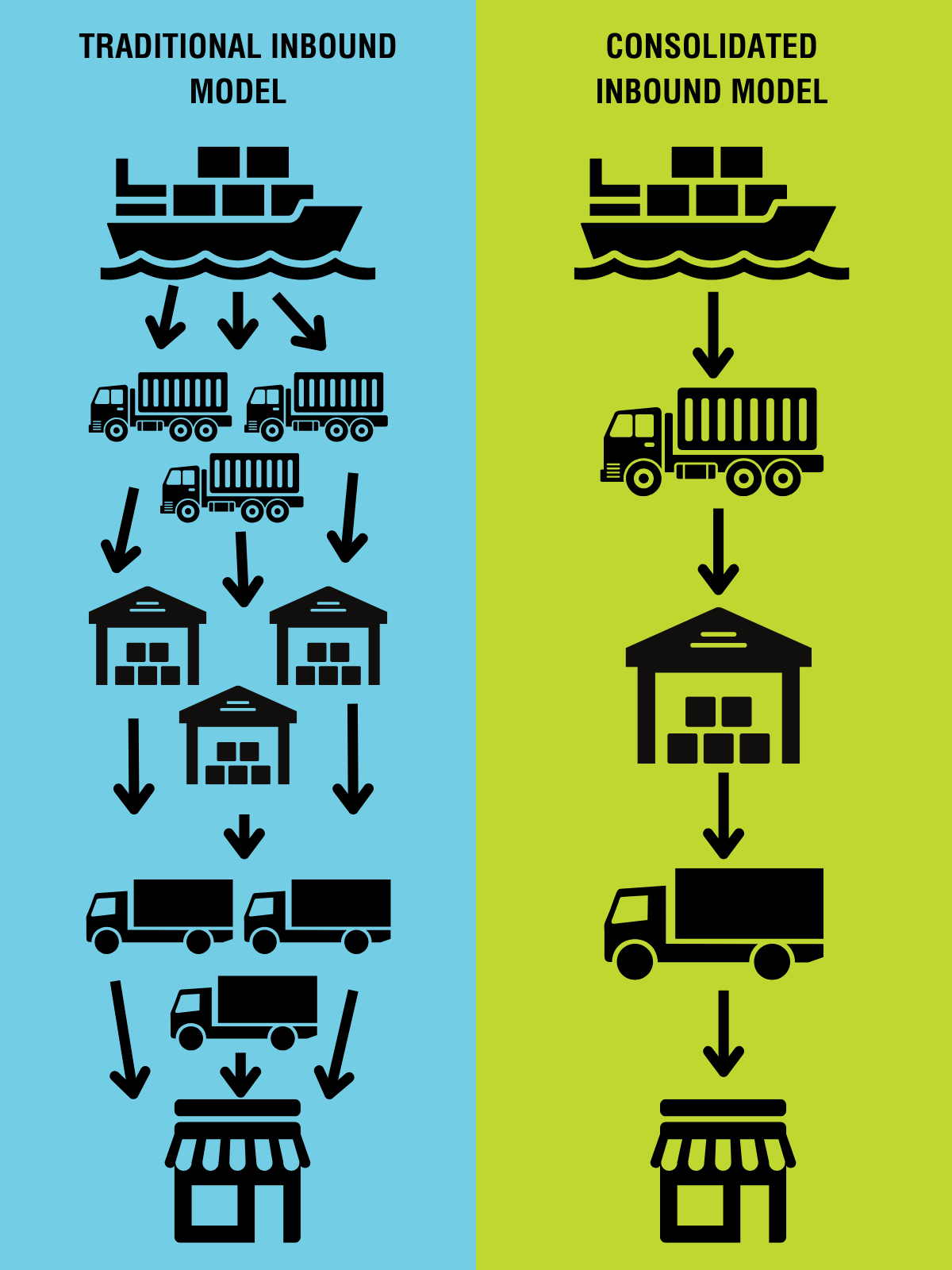

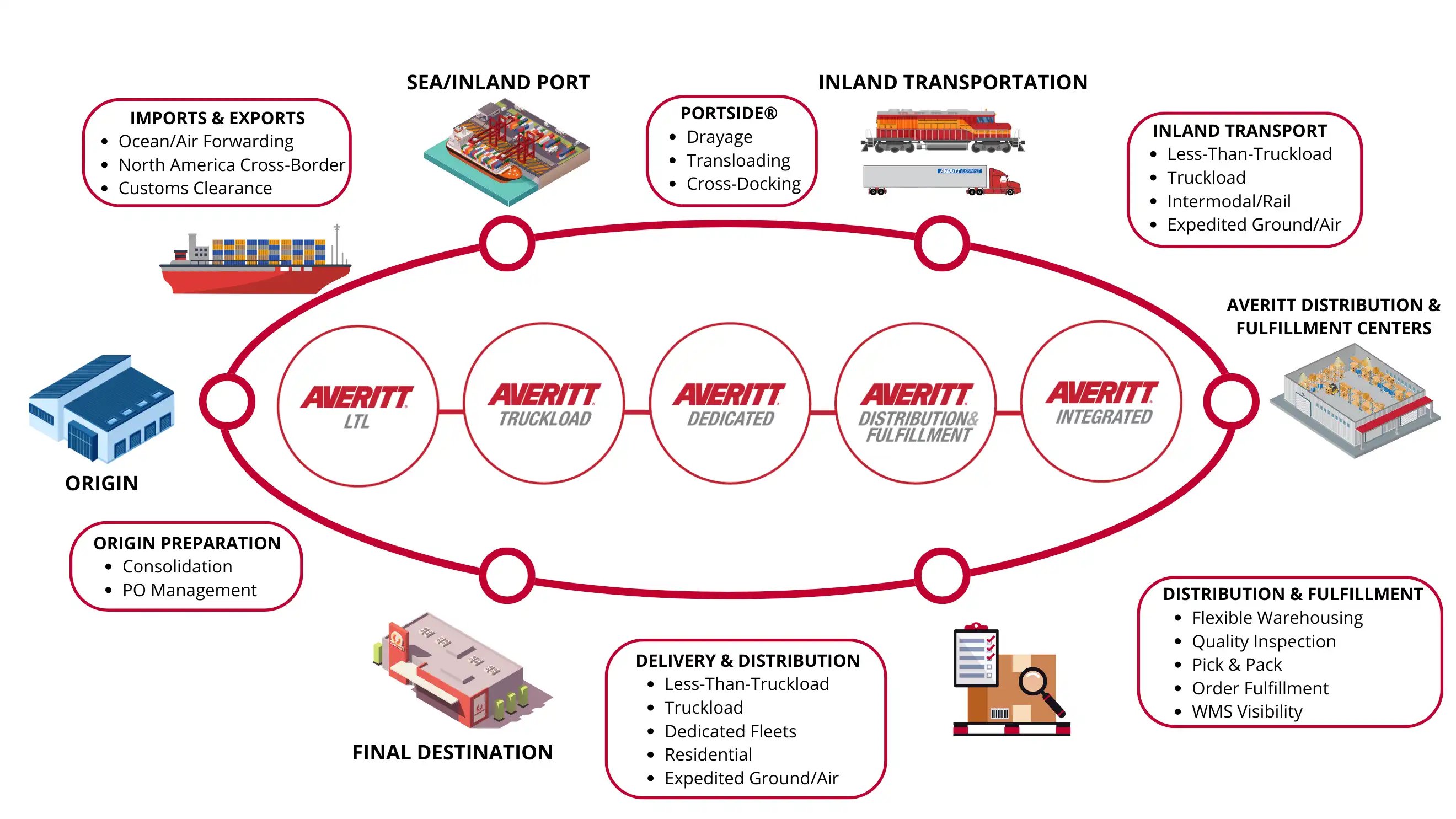

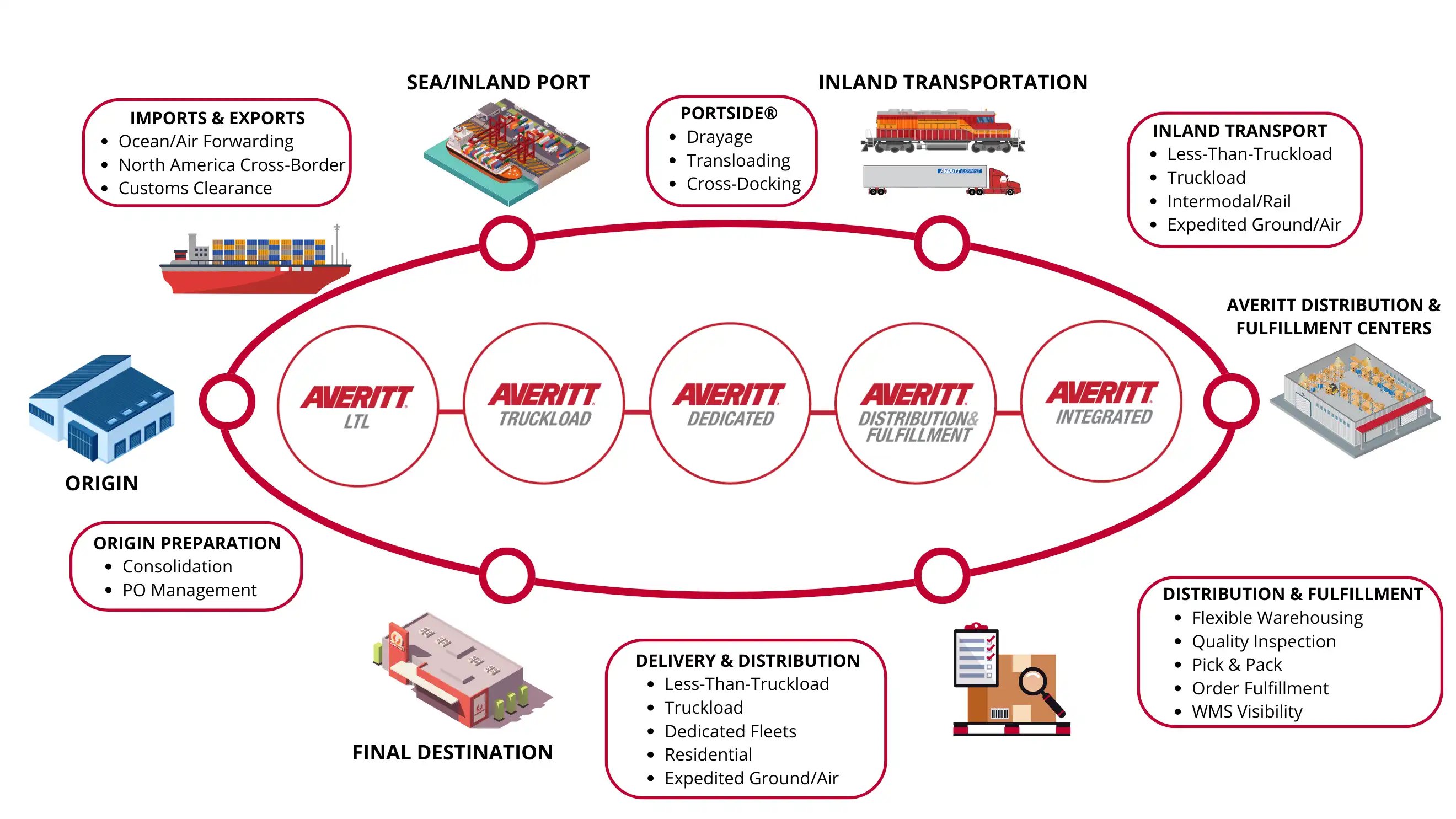

Traditional inbound models often involve a patchwork of disconnected providers. A container may arrive at port and be handled by a drayage company, then a transload facility, then an LTL carrier, then a distribution center—and that’s all before the product reaches the end customer. Each handoff is a point of risk: delays, damage, missed deadlines, billing surprises.

Averitt’s white paper, Streamlining Inbound Cargo Logistics, backs this up. It outlines how reducing touchpoints can dramatically improve speed to market, inventory accuracy, and cost control. The fewer times freight is touched, the lower the risk.

Port Strategy Isn’t Optional Anymore

Ed recalled the opening of Averitt’s Charleston PortSide® Distribution and Fulfillment Center in 2017 as a pivotal moment. It was Averitt's first hybrid location offering port drayage, transloading, and warehousing under one roof—also tying direct into Averitt's LTL and Truckload network.

"We didn’t know it then, but it became the prototype for how our entire Distribution and Fulfillment network would evolve."

Today, Averitt operates PortSide® facilities at major sea and inland ports across the U.S. These locations provide immediate access to container chassis, in-house drayage drivers, and inventory visibility tools. The result? Shippers can bypass third-party bottlenecks and keep freight flowing.

The white paper explains this well: "By partnering with a company that has its own container chassis and drivers, you eliminate the pitfalls and confusion of managing multiple drayage carriers." Instead of stopping the clock to troubleshoot, you're staying on schedule.

Avoiding Demurrage and Per Diem Fees

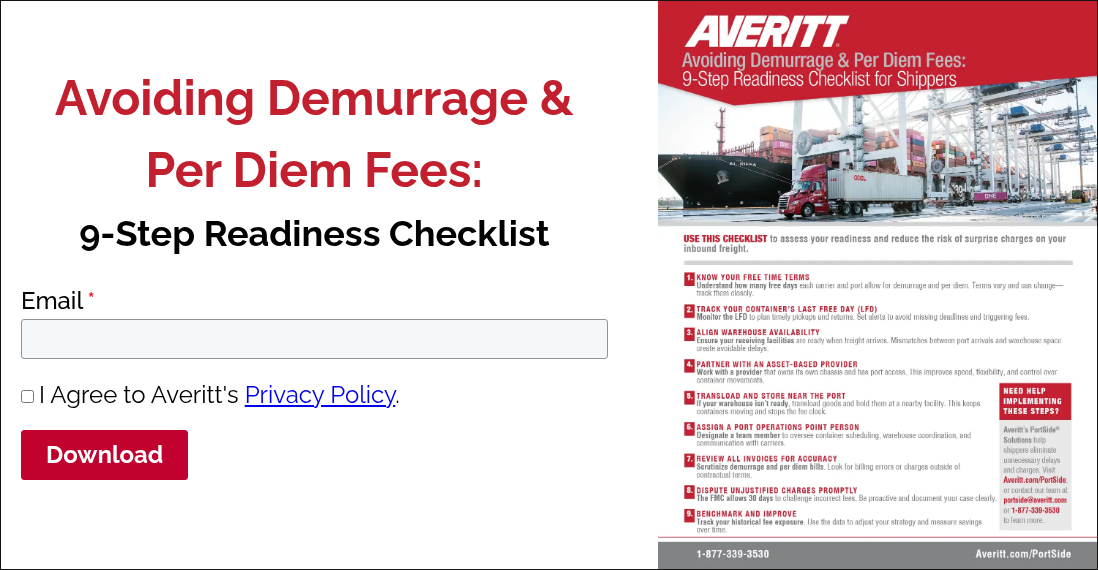

Poor coordination between ports, warehouses, and carriers doesn't just cost time—it can rack up serious fees. Our recent article Eliminating Demurrage and Per Diem Fees outlines how shippers are increasingly penalized by delays beyond their control.

To help, we created a 9-step checklist to reduce surprise container charges. A few highlights:

-

Know your free time terms

-

Align warehouse availability before freight arrives

-

Track your container’s Last Free Day (LFD)

-

Use asset-based partners with port access

Averitt’s PortSide® Services are purpose-built to address these challenges. With transload and short-term storage options near major ports, shippers can keep cargo moving—even when downstream facilities aren’t ready.

Also see: The Benefits of Transloading

From Port to Inventory, Without the Middlemen

Ed emphasized that a major turning point for Averitt was not just investing in buildings and trucks, but connecting them. "When you unify port operations, warehousing, and final-mile under one roof, you're giving customers continuity."

This matters because handoffs introduce fragmentation—different systems, different contacts, and different standards. With Averitt, the process becomes continuous:

-

Container arrives → PortSide® team drays it to nearby warehouse

-

Cargo is transloaded and inventoried using WMS integration

-

From there, it's distributed using Averitt’s own LTL, truckload, or final-mile network

This isn't theory. It’s in practice at facilities across Atlanta, Dallas, Nashville, and beyond—with over 3 million square feet of space in play.

Discover how Averitt helped Spectra Gutter Systems overcome bottlenecks in their inbound cargo flow by unifying drayage, warehousing, and fulfillment. Their story brings Averitt's Power of One model to life—and demonstrates what true visibility and efficiency look like. Watch the video below to learn more.

My name is Alan Hensley. I work for Spectra Gutter Systems and based in Atlanta, Georgia. We're the largest manufacturer of what they call gutter rainware. We manufacture from the raw material that comes in, and then we have our branches around the country, and we retail it out from there. Our manufacturing has grown, and we are now into importing. And so that's allowing us to use Averitt for importing. They also have the fulfillment centers where we can store stuff or have it transloaded. Alan contacted me and wanted to know if we could be of assistance. We were able to create a solution where Averitt will dray the containers when they come in to either our distribution and fulfillment centers to transload or directly to Spectrum gutters. Back in 2017, we started out using Averitt to do some of our truckload logistics to our different branches. And over time, we integrated the LTL system as well into a 3PL system we already have. They're able to help us get our new product we're having made overseas into the port and then to get it to our facility in Atlanta. I don't have to worry about having different people to pick it up at the port and different people to get it to us. It's just one place, one stop, and they handle it from there. Our technology will give them complete visibility of their product from the time that it ships to the time it arrives to their door. You know, we want it looking pristine when it gets there. The box is not crumpled and torn up. That says a lot as well. So they transport that when it leaves our facility in that condition and it gets to the customer in that condition. Our goals for the future for Spector Gutter Systems is to be in all the states, across the country. We have a five-year goal to have be a billion dollar a year company, and we're gonna need lots of transportation. They're gonna need a great partnership like we have, with Averitt. This allows us not to have to slow down, but we can keep it going to where we have facilities to store it in in the fulfillment centers that are out near our branches. And then we can propagate it out from there and it goes across the country. So they'll be a big part of helping us to grow. I think we can help them put their product in different locations to beta test on areas they wanna grow in without making a full commitment of staff and resources. That is a great enhancement and a great partnership because as we grow, we don't have to necessarily put on drivers and trucks right away to be able to do that. We can use their system and their dedicated drivers to be able to do that. There's that Power of One to help us to grow. Well, the reason why we're calling it Power of One, is Spectra Gutter Systems are using our truckload, our LTL, and are integrated to provide solutions for them. We are also expanding into distribution and fulfillment as well as possibilities of dedicated that would help them grow closer to that one billion dollar goal. It's the power of one company being able to meet all of my logistic needs. The deal about Power of One - I always like to come back to the relationship. Averitt believes in taking care of the relationship and and the person, not just the business. Whatever my problem is, they are solution to help us to solve it. And they will go to whatever extreme it needs to be to make it. Whether it's making room in a warehouse, it doesn't matter. I want a partner that's like that and Averitt fulfills that for us.

A Logistics Partner, Not Just a Provider

Ed encourages shippers to ask themselves a fundamental question:

Am I partnering with a vendor—or a value creator?

"The companies that have weathered the volatility of the past few years aren’t the biggest ones," he noted. "They’re the ones that made strategic choices—who they trusted, how they built flexibility into their network, and how quickly they could adapt."

Averitt’s Power of One concept is based on end-to-end control with a single point of contact and a single trusted partner. That stability means fewer breakdowns, fewer blind spots, and far greater visibility.

Final Thoughts: Rethink, Then Simplify

Inbound logistics doesn’t need to be a maze of providers, trackers, handoffs, and escalations. Whether you're struggling with unpredictable container arrivals, climbing drayage bills, or missed delivery windows, the solution often lies in consolidation—not complication.

Download our full white paper, Streamlining Inbound Cargo Logistics, to explore real-world strategies for simplifying your supply chain from the port to your warehouse door.

And if you're tired of surprises on your next invoice, grab our Demurrage & Per Diem Checklist to start gaining control today.

Fewer touches. Smarter strategy. Greater peace of mind.

That’s the Power of One.

Ready to simplify your inbound strategy? Let’s talk. Fill out the form below to connect with a supply chain specialist and discover how Averitt can help you reduce costs, increase visibility, and streamline every mile of your inbound freight journey.

.png?width=542&height=179&name=PNG-Averitt%2055%20Years%20RED%20ODFIP%20(1).png)