The shipping industry can be complex and constantly changing, much like a challenging puzzle with moving pieces. For those involved in shipping freight and managing logistics for a business, this means facing a series of obstacles.

In this article, we delve into five prominent issues that shippers frequently face. However, our primary objective is not only to identify and discuss these challenges but also to offer comprehensive solutions and recommendations.

1. Tracking Shipments

Effectively tracking shipments is vital but can pose a significant challenge depending on the carrier that you choose. Not all carriers have reliable tracking systems or the technology to provide timely updates. This might give you a delivery date but with few real-time updates, or sometimes updates that aren't very reliable.

At Averitt, customers have access to shipment visibility through our website, automated SMS and email notifications (E-Notifications), and our around-the-clock, centralized customer service team. Additionally, we offer a host of data integrations, including EDI and API feeds, to seamlessly connect our systems with those of our customers. These offerings provide shippers with accurate freight tracking and necessary support at every turn.

2. Getting the best price

Regardless of what you're purchasing, ensuring you're getting a fair price is often a top priority. However, determining if you’re getting the best price can be difficult – especially when it comes to freight transportation.

In many cases, freight quotes are based upon a fixed market price. Fortunately, dynamic pricing technology is making shopping for freight rates more flexible and transparent than ever before.

But remember, the cheapest option isn't always the best one. Cutting cost on the shipment might sound great, but what you pay in damages could end up costing you more in the long run. It’s important to find the right balance between price and service quality.

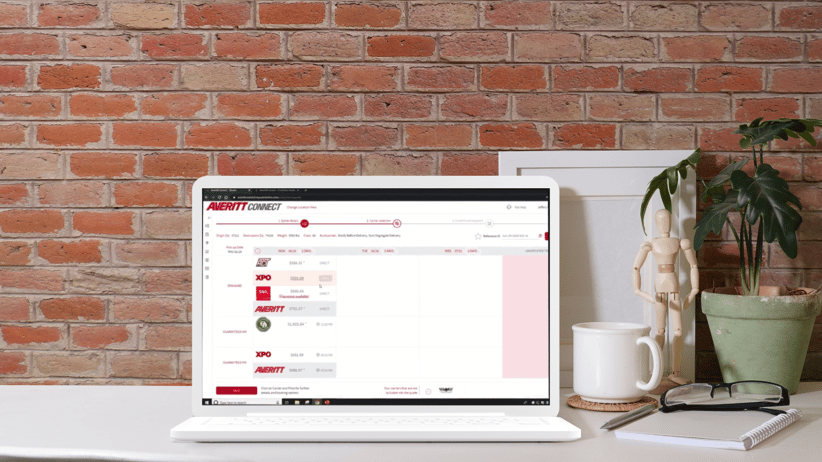

Averitt’s dynamic pricing tool, ExactRate®, uses various real-time factors to provide rate quotes for shipping freight. For instance, you might get a lower price for shipping on a specific day of the week or if your shipment is moving in a specific lane that has more capacity at a given moment in time. We also offer Averitt Connect, a direct-to-carrier transportation management software that lets you compare rates from different carriers, helping you choose the rate quote that’s best for you.

3. Damages

Dealing with damages during transportation can be costly, and while both the carrier and the shipper share this responsibility, some issues can be traced back to improper packaging and palletizing.

To minimize the risk of damages, it is wise to consider exploring various methods to ensure proper palletizing and packaging, such as:

- Secure Stacking: Stack items in a way that ensures stability and prevents collapsing or shifting during transport.

- Use of Strapping and Stretch Wrap: Employ strapping or stretch wrap to bind items firmly to the pallet to help maintain integrity during handling.

- Sealing and Taping: Properly sealing and taping packages helps avoid any exposure to external elements that might compromise the content.

Watch the video below to learn about the "rigors of freight in transit."

When freight is handed off to Averitt, we load it like we own it with the goal of delivering each shipment on time, on target, and intact. In order for us to be successful, there are steps required of the shipper to help their freight move without unnecessary delay or damage. The proper completion of the bill of lading, address and handling labels, as well as proper packaging will result in a quality finish. Averitt has a fantastic freight protection guideline resource available online or through your transportation specialist to assist with the basic preparation of freight based on the National Motor Freight Classification publication. The NMFC is the freight classification publication provided by the National Motor Freight Transportation Association, which not only identifies what classification will apply for pricing and cargo claim liability, but also outlines minimum packaging requirements by commodity. It further outlines what is necessary to protect the different sizes, shapes, and weights of freight that travel together within the same trailer while experiencing the normal rigors of less than truckload transportation. The rigors of transportation begin the moment we take off into traffic. The inertia will push freight to the rear of the trailer, so our platform associate will attempt to stack right, block in, and secure with strapping or bracing. Let's take a look at the effect this rigger has which increases the likelihood for damage to any falling freight and anything else around it. How the freight is packaged by the shipper will be influential to if any damage occurs. Let's look at the moments following the fall of those tires and see what happens as we drive over a pothole, railroad track or speed bump. Keep your eye on the top two loaded pallets and the bounce that is generated. This can happen and over again as we move through the city or over the road resulting in continual impact to the freight underneath. Packaging is essential to protect shipments as they bounce within the trailer. The force of the repetitive vertical impact as shipments are transported around the corner or hours to the next point could result in poorly built crates falling apart, plastic wrap loosening from the shipment, or the perception of damage from dented exterior cardboard containers. That's why we use cardboard as required under stacked pallets, pails, drums. It will absorb the vibration and cushion any bounce to help protect the floor loaded freight and may be an easy way for the shipper to beef up their packaging with very little additional cost. We also have to be cognitive of the weight of top heavy freight. Let's see why. After we recoup the load and continue our drive, we continue to see the effects of vibration. Did you know that vibrating or bouncing top loaded freight creates increased compression g force on floor loaded freight as it moves? It can be increased as much as ten times over the rear axle. That means these truck tires weighing a hundred and ten pounds each can produce compression weight of up to five thousand five hundred pounds when top loaded. Take a look at the floor loaded freight as we move down the road and see if it can survive the five hundred and fifty pounds stacked on top. I guess you saw that one coming. Two additional items we can take away from this failure is one, a crate is not a crate just because it's called a crate. Use Averitt's freight protection guidelines mentioned at the beginning of this video to strengthen packaging or ask your transportation specialist to get our loss prevention team involved. Secondly, we must make every effort to reduce the effect of vibration and load shift by filling all voids and trailers to provide stability to the packaging. We do this by using upright pallets or non unitized freight to fill the gap, meaning these items will come in contact with your freight. Let's also take this time to show the reason why we use cardboard under loose drums. The drum with a sheet of dunnage under it remains within its footprint while the drum without it slides to the rear of the trailer. If you notice, there is a hazardous label on the drum so this could make any one of us have a bad day. It is best to palletize drums on a solid bottom pallet with cardboard underneath it. Keep your eye on the television loaded to the side of the wall. It is a challenge to protect single loose pieces such as this television during the normal rigors of transportation, so solid exterior and interior packaging is important for any loose piece. As we continue on our journey, the wrap on these filters become loose and they begin to fall. If you look closely, you'll see crushing to the filters on the bottom of the pallet. Oh, yeah, we can't ignore the water heater shifting. Takeoffs, turns, curves, and continued vibration will take its toll on this freight. Now imagine being the one having to present this to our mutual customer at delivery. Sometimes we may load a trailer to protect from stacking by using pallet decks. This is the right thing to do, however freight stacked on a deck can still be damaged. In this case, it appears we may be lucky because the roof of the trailer is helping keep the shipments from falling over. However, there is still potential damage within the container due to the intense rocking motion. No, there it goes, down for the count. Also notice the box to the left that was damaged from the banding cutting into it while rocking front to rear. Product damage may also have occurred. Just five more minutes down the road and we see more falling freight. Earlier, we observed why it's important to package well, block freight in and secure it keeping in mind that the energy in a takeoff will push freight to the rear of the trailer. Likewise, we have to be aware that all braking will result in freight being pushed to the nose of the trailer. Observe as we see what the normal rigor of transportation of hard braking will do to this loose TV. Now let's zoom out and see what all of this freight does. Did you see the impact all the freight experienced? If not protected properly, commodities can experience preventable damages as a result of the rigors of transportation all freight will experience. These rigors can be protected from through adequate internal and external packaging, proper loading disciplines, and educational tools like this video and our freight protection guidelines. Commitment is that we will take ownership in a way that separates us from our competition. We must load it like we own it and partner with our shippers to provide a quality start as we exhibit the power of one to our mutual customers.

For more comprehensive insights on safeguarding your freight and optimizing your shipping processes, download our Freight Protection Guide!

4. Port Congestion/International/Cross-Border

Dealing with international cargo, whether it’s arriving or departing, can be a logistical nightmare. This is especially true when your port of choice is congested, resulting in delays. Navigating through this complexity can be exceptionally demanding, given the inherent unpredictability associated with ports and border crossings.

Exemplifying the fickle nature of managing international cargo, there have been occasions when congestion in the Panama Canal surged, due to restrictions on the number of ships allowed through the waterway.

To mitigate the potential for delays in international shipments, opting for a service provider with diverse transportation and logistics capabilities is crucial. At Averitt, we leverage our five service units to help get around congestion and sail through the rocky waves of international cargo.

For instance, when encountering congestion at the Port of Charleston, Averitt can redirect to the Port of Savannah, leveraging their services to bypass delays that come with multiple carriers. The Averitt team collaborates internally to assist with transloading, intermodal transport, and more to ensure your freight stays on track.

5. Freight capacity

Freight capacity is a highly dynamic and unpredictable aspect of the shipping industry.

Managing freight capacity is like balancing on a tightrope, where market demands can quickly shift, resulting in either too much or too little space. Adapting to the varying demand requires meticulous planning and a deep understanding of logistics.

A discrepancy in capacity can lead to delays in shipments, higher costs, and potential disruptions in the supply chain. Understanding and navigating freight capacity challenges is crucial for businesses to meet delivery commitments and maintain operational efficiency.

The most effective strategy for navigating these challenges within the shipping industry involves establishing a partnership with a dependable and high-quality carrier. This carrier becomes an integral part of your success.

When you form a partnership with a dependable service provider that possesses a robust infrastructure, highly skilled teams, and a diverse array of solutions, it helps you handle the complexities of the industry. By building a solid partnership with such a carrier, shippers can strengthen their ability to handle operations, work more efficiently, and guarantee that their cargo arrives safely and on time.

.png?width=542&height=179&name=PNG-Averitt%2055%20Years%20RED%20ODFIP%20(1).png)