For decades, China has been the engine room of global manufacturing. From electronics to apparel to consumer goods, the world has relied on China’s scale, labor force, and infrastructure to keep supply chains humming.

But recent years have exposed the vulnerabilities of leaning too heavily on one country. Trade tensions, tariffs, COVID-19 disruptions, rising labor costs, and geopolitical uncertainty—particularly around Taiwan—have all contributed to a growing realization: single-source strategies are high-risk strategies.

Enter China+1—or as many shippers are now realizing, China+2 or +3. This evolving sourcing model doesn’t mean abandoning China. It means building resilience by expanding beyond it.

What Is China+1—and Why Is It Evolving?

The China+1 strategy emerged as a risk mitigation play: companies would maintain operations in China while shifting part of their manufacturing or sourcing to an additional country. It helped spread risk, reduce tariff exposure, and diversify capacity.

But now, leading businesses are going further.

They’re not just adding one country—they’re building a multi-country sourcing ecosystem. Whether it’s Vietnam, Mexico, India, or Eastern Europe, organizations are weaving in two or three alternative locations to enhance agility and reduce supply chain disruption.

Why the Shift?

- Tariff Risk: While the U.S. has imposed tariffs on numerous countries in 2025, China has been among the most heavily targeted.

- Geopolitical Pressure: Uncertainty around the Taiwan Strait and broader U.S.–China relations have raised concerns about overexposure.

- Pandemic Lessons: COVID-19 lockdowns highlighted the danger of concentrating production in one location.

- Strategic Evolution: Supply chains are no longer optimized for cost alone—they’re now built for resilience.

"One supplier is a risk. Two is a strategy. Three is resilience."

From China+1 to China+Many: Where Are Companies Going?

As companies look beyond a single sourcing destination, many are turning to a blend of regions that offer complementary strengths. Instead of replacing China entirely, they’re building diversified networks designed for agility, proximity, and risk reduction.

Here’s a look at where companies are expanding—and why those countries are gaining traction:

|

Country |

Industry Strengths |

|

Vietnam |

Electronics, textiles, furniture |

|

India |

Pharmaceuticals, auto components, chemicals |

|

Mexico |

Auto, electronics, nearshore assembly |

|

Poland, Romania |

Machinery, light industrial goods |

|

Indonesia, Thailand |

Textiles, consumer goods |

Logistics Complexity—And Opportunity

Of course, spreading sourcing across multiple countries introduces new challenges:

- Lead Time Variation: Delivery timelines shift dramatically depending on origin port and inland infrastructure.

- Customs Complexity: Navigating multiple regulatory regimes and trade compliance policies.

- Multi-Lane Transportation: Coordinating intermodal, cross-border, and final mile delivery.

- Visibility and Communication: Managing real-time tracking and communication across time zones and languages.

Yet these same complexities present advantages when managed with the right strategy:

- Nearshoring from Mexico reduces transit times and limits exposure to U.S. West Coast congestion.

- Multi-origin sourcing gives you flexibility when geopolitical or climate events threaten a specific region.

- Integrated logistics partners that offer international forwarding, drayage, warehousing, inland, and final mile delivery can turn a complex network into a seamless one.

Real-World Logistics Solutions

Companies that succeed in multi-country sourcing often work with logistics providers who:

- Have in-house bilingual staff or partners foreign trade hubs

- Offer in-house customs clearance and trade compliance expertise

- Provide visibility across ocean, air, road, and rail modes

- Help test new sourcing routes before full rollout

FACT vs. MYTH: Understanding China+1 Diversification

|

MYTH |

FACT |

|

China+1 means companies are pulling out of China entirely. |

Many companies are retaining China as a key supplier while adding new regions. The strategy is additive, not subtractive. |

|

Only small or medium-sized enterprises are pursuing diversification. |

Major global brands—from auto manufacturers to tech firms—are leading the charge into multi-country ecosystems. |

|

Nearshoring is just a trend—it will fade. |

Nearshoring to Mexico is a long-term structural shift, supported by trade policy and infrastructure investment. |

Real-World Example: Planning Ahead Pays Off

One global kitchenware company previously relied on China for 80% of its production, with the remaining 20% sourced from Vietnam. But anticipating the potential impact of escalating tariffs, the company made a proactive shift in early 2025—flipping that ratio to 80% Vietnam and 20% China.

That foresight paid off. When new tariffs on Chinese-made goods took effect, the company avoided major cost spikes, kept its inventory flowing to consumers, and maintained consistent lead times. Their success wasn’t just about strategic sourcing—it was also about execution. With Averitt managing their international forwarding and customs clearance, the transition was seamless.

Final Thought: Resilience Is the New Advantage

In the past, success in supply chain management meant cutting costs. Today, it means reducing risk, improving responsiveness, and building resilience.

The China+1 model helped start that shift. But the future belongs to businesses that think beyond it—those bold enough to pursue China+2, +3, or more.

The most agile supply chains are no longer just made in China. They’re made around the world—by design.

Ready to Build a More Resilient, Globally Connected Supply Chain?

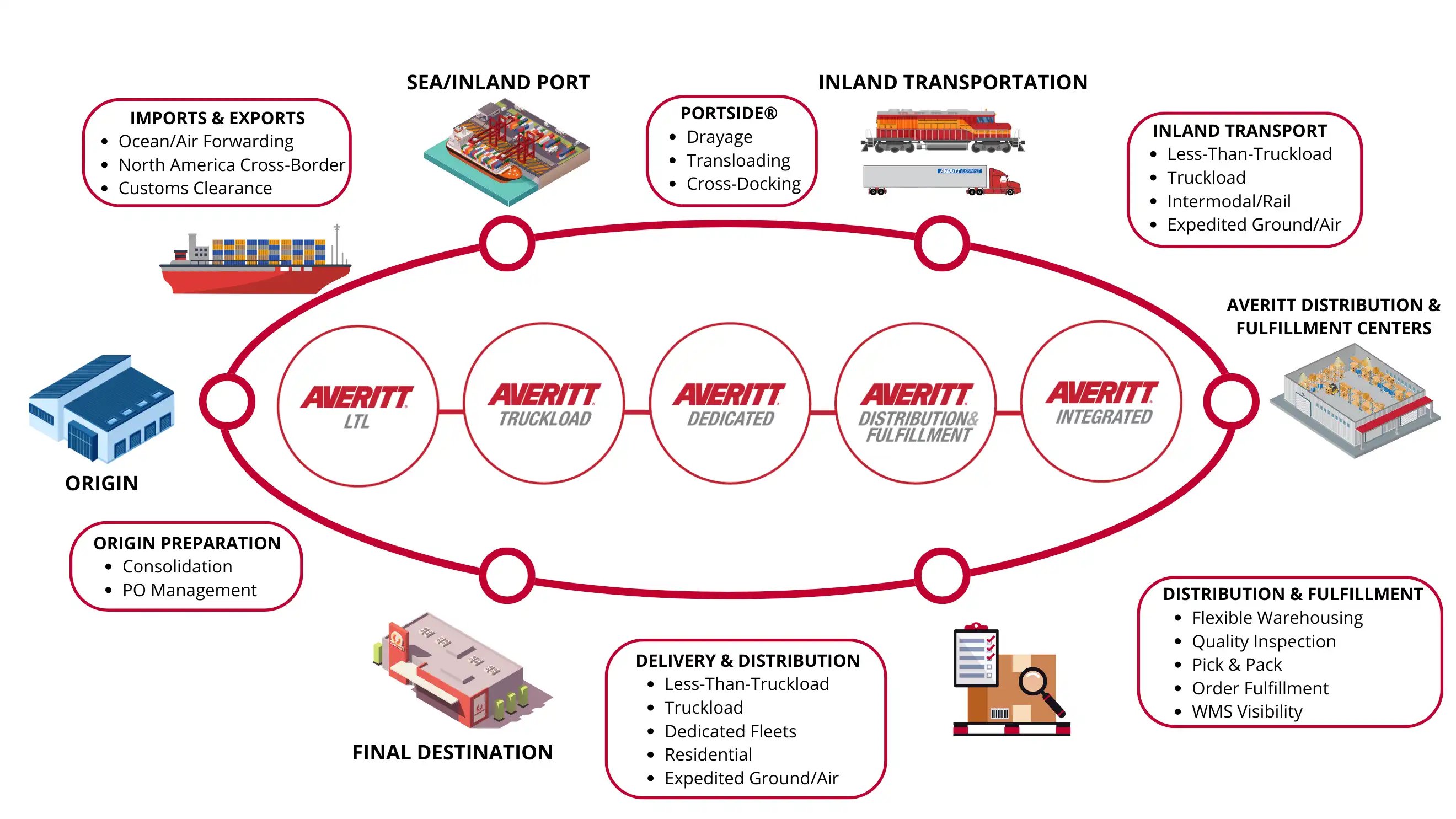

From managing port-to-door freight to supporting long-term sourcing shifts, Averitt has the international logistics expertise to help you execute with confidence.

- International ocean/air forwarding and customs clearance for imports and exports in 100+ countries (Licensed NVOCC)

- Asset-based drayage and transloading across major U.S. gateways

- Cross-border solutions throughout North America

- Scalable LTL and TL transportation

- Distribution and Fulfillment solutions to support inbound cargo flow, eCommerce, and inventory replenishment across the U.S.

- One point of contact and 24/7 U.S.-based customer service

Whether you're rebalancing your sourcing network or scaling into new regions, Averitt simplifies global logistics—so you can focus on growth, not complexity.

Talk to our team today to start your multi-country strategy with a partner who can deliver every step of the way. Fill out the form below or visit our International Services page for more information.

.png?width=542&height=179&name=PNG-Averitt%2055%20Years%20RED%20ODFIP%20(1).png)