Identifying the most optimum distribution strategy is crucial for shippers to streamline the movement of goods and enhance supply chain efficiency. There are two primary types of distribution strategies that leverage warehouses to stage freight for distribution to final destinations: regional and centralized.

Understanding Distribution Models

Selecting between these two methods is crucial as it enables shippers to customize their strategies, reduce expenses, and surpass customer expectations to gain a competitive advantage and achieve long-term success.

Regional Distribution

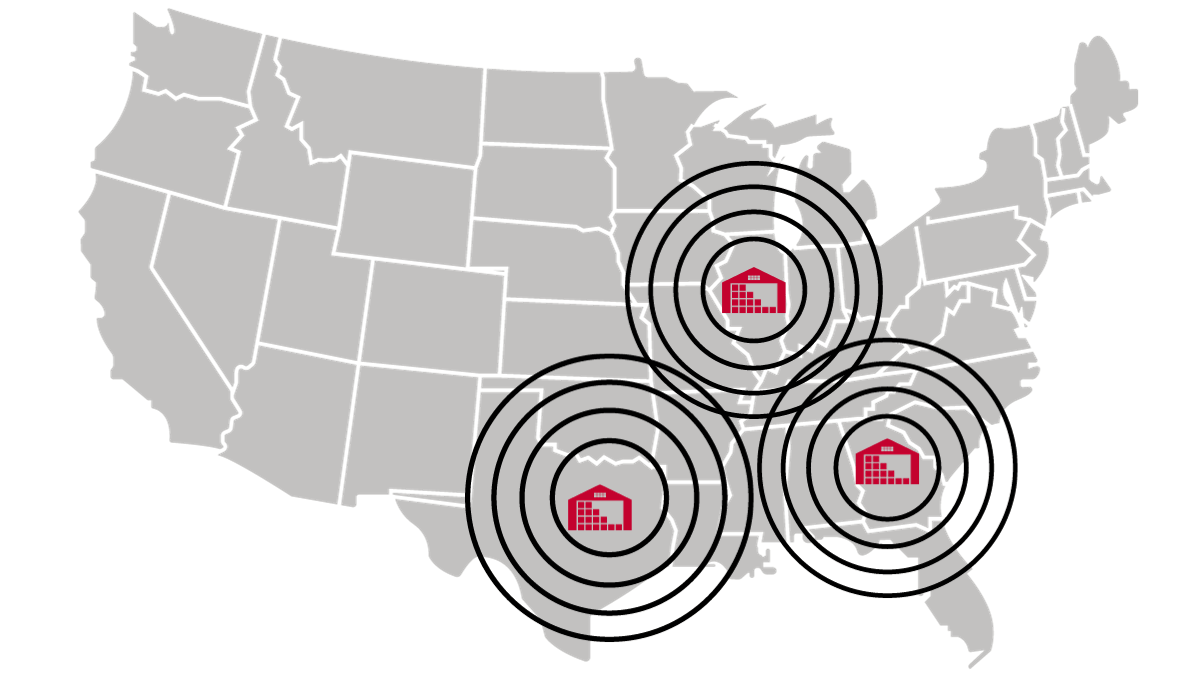

Regional distribution involves the strategic placement of multiple distribution centers across different geographic regions of your business. These distribution centers act as pivotal hubs for managing and distributing goods to serve local markets efficiently.

For example, your business may use a distribution center in Dallas, TX to serve the Southcentral U.S., while using distribution center in Peoria, IL to serve the Midwest and a distribution center in Atlanta, GA to serve the Southeast.

Benefits:

- Quicker deliveries due to proximity

- Adaptability to regional demands and preferences

- Reduced transportation costs for shorter trips

- Small-scale testing to help make data-driven decisions

Challenges:

- Balancing varying inventory levels across regions

- Potentially higher operating costs

Leveraging a regional distribution strategy doesn't necessarily require a shipper to own or lease out entire warehouses in multiple markets. That's where multi-client warehousing solutions steps in...

Multi-Client Warehousing

Leveraging multi-client warehousing solutions within a regional distribution strategy can significantly cut costs and optimize supply chains. Operational expenses are shared among clients, lowering costs for storage, labor, and logistics. This efficient setup can also provide scalability, adapting easily to changing business demands and seasonal fluctuations.

More importantly, by tapping into the service provider's potential logistics expertise, assets, trained associates, and established distribution network, shippers can streamline their supply chain and increase their velocity to market.

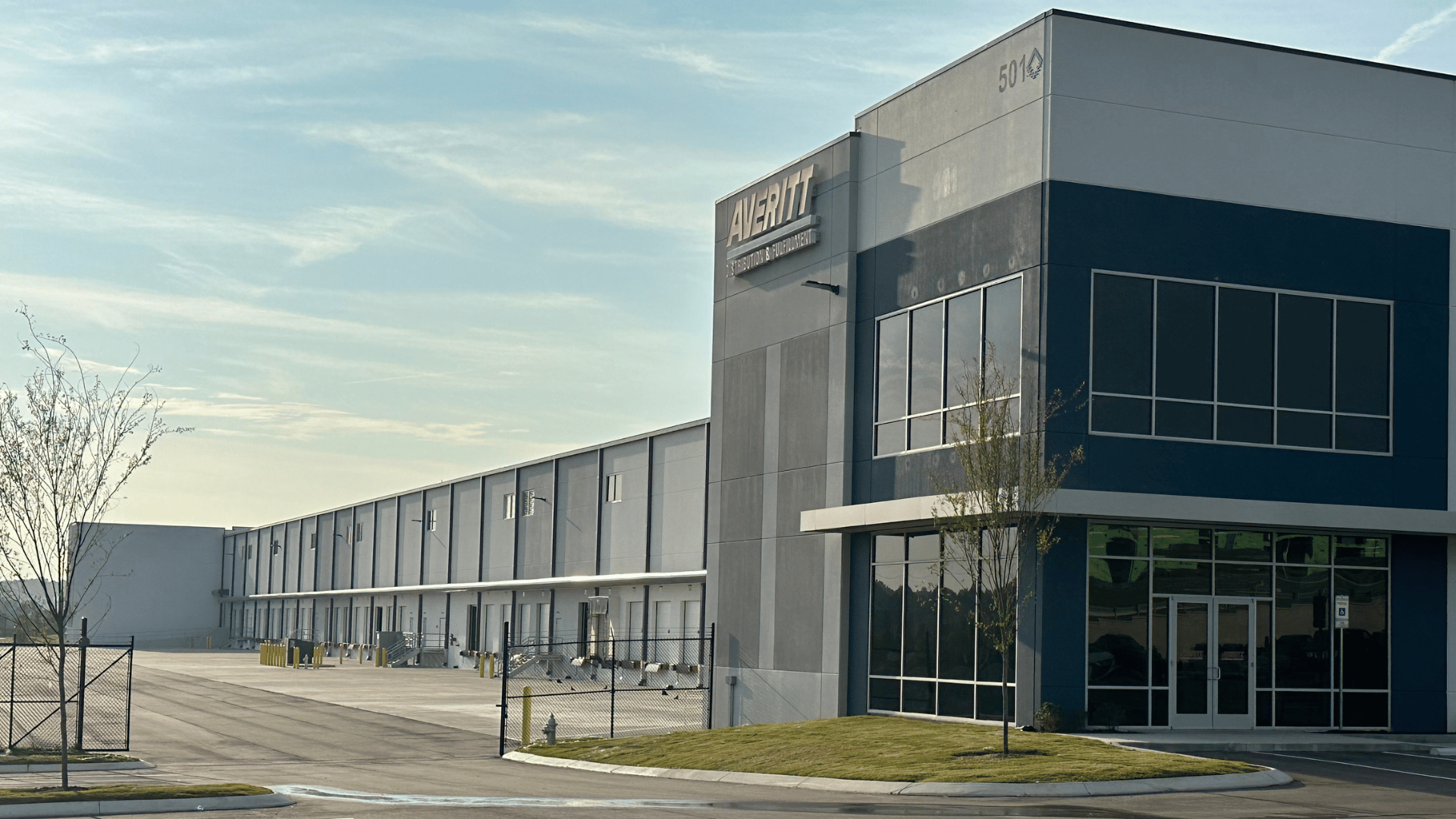

Averitt Distribution and Fulfillment offers shippers quick and flexible access to over 40 multi-client warehousing locations throughout the U.S. where freight can be staged, managed, and efficiently delivered to any point in North America. Watch the video below to learn more.

whether your business specializes in e-commerce shipping or automotive parts distribution your industry is our industry and with Averitt distribution and fulfillment solutions we can help you position your business for better speed to market all while enabling you to reduce your overall costs from point A to point B through our network of fully staffed and secure locations across the southern and central United States we can handle any need big or small from shared distribution space to dedicated facilities from pick and pack shipments to LTL and full load distribution we put your needs first with customization and control you won't find anywhere else so that you can reach your customers anywhere in North America or around the globe by land rail air or sea straight to their receiving dock or room of choice all with complete inventory and shipment visibility through our warehouse and transportation management technologies giving you a clear view of your business from home or in the office all with the simplicity of one contact one invoice zero worries that's the power of one

Centralized Distribution

Centralized distribution is a strategic logistics approach that involves the consolidation of distribution activities within a central hub. This central hub (distribution center) acts as a primary point for inventory consolidation, sorting, and dispatching to various destinations.

Centralized distribution becomes particularly advantageous for shippers who operate over extensive geographical areas. This strategy allows for the effective orchestration of logistics from a single hub, facilitating streamlined distribution to various locations. It's especially beneficial when managing a large volume of goods, as it enables economies of scale, thereby reducing the per-unit cost of handling these goods.

Depending on the square space needed by a shipper, a multi-client facility could potentially meet the necessary requirements. For high volume shippers that need tens of thousands of square feet, or even hundreds of thousands, a dedicated distribution center could provide the most efficient solution for a centralized strategy.

Evaluating the Approaches

Now, let's delve deeper into the key distinctions between regional and centralized distribution strategies.

Delivery Speed

Regional distribution enables faster deliveries within a specific region as distribution centers are strategically located near target markets, ensuring prompt delivery to meet customer expectations.

On the flip side, centralized distribution may experience potential delays owing to the longer distances between the central hub and various destinations. As the distribution activities are consolidated into a central hub, the products need to be transported over longer distances to reach different regions. This can result in increased shipping time and potential delays in delivery.

Inventory Management

When it comes to inventory management, the choice between regional and centralized distribution strategies can have a significant impact. Regional distribution may lead to stock imbalances across different centers. Each distribution center operates independently, which can result in variations in inventory levels and potential challenges in coordinating stock across regions. This approach may require shippers to invest more time and effort in managing inventory and ensuring consistent stock levels.

On the other hand, centralized distribution offers unified inventory management, which can greatly simplify the forecasting process and improve stock level optimization. By consolidating all inventory into a central hub, shippers have better visibility and control over their stock. They can more accurately track inventory levels, monitor demand patterns, and make data-driven decisions regarding replenishment and allocation. This centralized approach streamlines inventory management, reduces the risk of stock imbalances, and allows for more efficient use of resources.

Either way, utilizing a warehouse management system will help ensure businesses cover their bases when it comes to inventory visibility, planning, order fulfillment, and restocking.

Cost

When considering the cost implications of choosing a distribution strategy, it is crucial to evaluate the potential savings and expenses associated with each approach. Regional distribution offers the advantage of shorter distances, resulting in reduced transportation costs in final mile delivery. Shippers can benefit from cost savings due to the proximity of distribution centers to local markets, allowing for more efficient and cost-effective delivery. However, managing multiple distribution centers independently can increase operational costs and requires effective management and coordination.

On the other hand, centralized distribution can provide savings in bulk storage, but may result in increased transportation costs due to longer distances between the central hub and various destinations. Products need to be transported over greater distances to reach different regions, which can contribute to higher shipping fees.

Flexibility

With regional distribution, adapting to local demand changes is easier as distribution centers are strategically placed in different markets. This allows for a more tailored approach to each market, but may require establishing new distribution centers in additional regions.

The centralized approach may require operational changes to adapt to market shifts, but can be achieved by expanding the existing central hub. This allows for efficient resource use and easier oversight of operations, accommodating increased demand without the need for new distribution centers.

Making the Right Choice for Your Business

When choosing a distribution strategy, consider your business size, product type, delivery timelines, budget, and customer expectations. Aligning your strategy with these factors will help you meet and exceed customer expectations.

It is worth considering the potential of hybrid distribution models that blend elements of both regional and centralized approaches. This can offer a versatile solution tailored to your specific business needs. By striking the right balance and aligning your distribution strategy with your overarching business goals and customer expectations, you can achieve operational efficiency, customer satisfaction, and sustainable growth in the dynamic landscape of transportation and logistics.

Averitt Distribution & Fulfillment

Averitt combines centralized and decentralized distribution strategies to offer a flexible solution. With over 40 locations and more than 3 million square feet of space, Averitt offers shippers the ability to deploy both regional and centralized distribution strategies. Averitt's approach ensures efficient distribution and fulfillment, whether you need to streamline inventory, reduce transportation costs, or improve delivery speed.

.png?width=542&height=179&name=PNG-Averitt%2055%20Years%20RED%20ODFIP%20(1).png)